Mortar Advice

Reading time: 6 minutes

What’s the difference between cement and mortar?

Although we’ve touched upon this, the answer explains why it’s good to make the distinction between cement and mortar for pointing, for example: cement is a powder that isn’t used on its own, and only as a part of other mixes. It’s mostly composed of marl, which is a sedimentary rock, clay and limestone. Cement is then used with fine sand and water to make mortar, and by adding aggregates, such as stones and gravel, you make concrete.

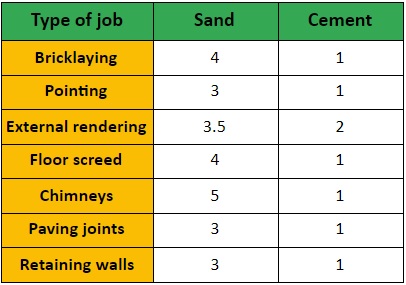

What’s the best mortar mix ratio?

Depending on the task at hand, the ratio can vary, with additional sand in the mix for extra stability, especially for load-bearing weights. The most important thing to take in consideration, however, is consistency. As a guide to thickness, if you tilt your trowel to around 90 degrees, the mix should hold its own and not slide off.

Mortar of differing strengths can cause major issues when building walls, as an inconsistent mix can lead to mortar drying at different times, leading to potential cracking. While that might not sound too serious, cracks in mortar can eventually lead to whole walls collapsing.

As there isn’t a ‘one mix fits all jobs’ solution to mixing the best mortar mix ratio, the below table will give you a general indication of what’s required for each type of job. Do bear in mind that you will need to add water to your mix, so by adding a little at a time you should be able to obtain the desired consistency and control the mix easier.

What is the best mortar mix for pointing?

We’ve touched upon the basics of mixing mortar, and with pointing there are some extra parts to consider. Here are materials to think about when mixing brick mortar.

-

Sand and cement

Sand and cement are key parts of any mortar mix, with the cement acting as the binding agent with the addition of water. However, for ease and time-saving, ready-mixed lime mortar is often a preferable option.

-

What is lime mortar?

Lime is a natural plasticiser, which means the mortar is much easier to work with, as well as providing other benefits which we’ll come on to later. Lime is often used when repointing older buildings, because it can be gentler to older brickwork than other chemical plasticisers.

-

What is mortar plasticiser?

Plasticisers are chemicals that are added to mortar mix to give a little more flexibility before setting, which is useful for noticing uneven patches and holes. Plasticiser also makes mortar set stronger, while making it more resistant to frost.

This should give some insight into the basics of mortar, and understanding what goes into making it. We’re here to provide everything you need to make pointing and masonry mortar, including essential tools, chemicals and compounds.

Mortar tips

We’ve covered some of the basics of mixing mortar, but there are some pieces of advice we can share to help.

Can I put new mortar over old mortar?

Simply layering new mortar over existing mortar is unlikely to work, as there’s not enough space for it to stick to. If you need to repair crumbling mortar in old brickwork, you will need to scrape it out using tools to tap away along the exposed, damaged mortar. Don’t dig straight into the mortar deeply, as this can cause further instability or even damage the bricks on the other side of the wall.

Once the defective mortar is removed, you should be left with a space between the bricks that is wide and deep enough to apply new mortar.

What tools can I use to remove mortar?

Power grinder with mortar rake – using a power grinder can make light work of jobs that can be time consuming by hand, and with the addition of a mortar raking disk, old mortar can be removed quite quickly.

Bolster chisel – this hand-held tool works by gradually taking off each layer of old mortar, by using the edge of the chisel. Bolster chisels are incredibly tough and are specifically designed for mortar and concrete.

Can the weather affect mortar?

Weather does have an effect on mixing and applying mortar. Without having adequate cover while mixing, rainwater will throw your mix ratio off. If mortar is too wet it will simply run out of the gaps between the bricks. Extreme cold also has a negative effect on mortar.

The water in your mix can freeze, so it’s advisable not to attempt to work with mortar when the temperature is under -5°C. If the weather is too hot, the mortar will dry out too fast and form a weak bond. While plasticisers can help when working in such conditions, it’s more advisable to wait until you can work outside of these extremes where possible.

Don’t mix mortar by hand

If you’re trying to fix a small area of mortar, hand mixing is a possibility, but for any project that requires a lot of work, get a cement mixer. This is the best way to ensure consistency and quality of mortar. If you need a cement mixer, we can help with our tool hire service.

We’re here to supply you with all the essentials you need for mixing mortar for new jobs, or repairing brickwork. Order directly from Travis Perkins online today.

Disclaimer: The information contained on this page is intended as an overall introduction and is not intended as specific advice from a qualified professional. Travis Perkins aims to avoid, but accepts no liability, in the case that any information stated is out of date.