Modern Methods of Construction

Reading time: 7 minutes

What are modern methods of construction? (MMC)

Modern methods of construction (otherwise known as MMC, ‘modular construction’ or ‘smart construction’) is a specialist process to replace the traditional ‘bricks and mortar’ building technique, using off-site unit construction at a factory which is then transported and put in place on-site. MMC aims to offer value for money, sustainability and speed, producing high quality buildings quickly.

There are seven categories of MMC, each with its own unique guidance, from pre-manufacturing to on-site completion. MMC uses modern technology and mass production methods to streamline the building process in a safe and efficient way.

Types of modern methods of construction (MMC)

MMC often uses factory-built modules which fit together, to form modern housing, offices, schools, sports centres and other buildings. MMC units can vary in type, usage and style, from prefabricated wooden frames for roofing through to modern technology 3D designs and even entire unit structures created off–site. Here are some examples of popular MMC types:

Timber frames

Hybrid MMC approaches can combine off-site engineering with on-site construction, such as timber frames for buildings. Instead of using labour on site, which can be costly and time consuming, it’s possible to prefabricate timber frames in a factory before transporting them to the site to be fixed in place. This not only saves time but reduces material wastage and mess.

Steel frames

Steel frames are a popular MMC method, helping to achieve a more eco-conscious building option than timber, as well as offering an impressive strength-to-weight ratio plus improved design flexibility. Prefabricated options include hot rolled fabricated steel, light gauge steel frames and hybrid techniques.

3D panelled units and volumetric construction

For modular building designs, precast 2D panelled sections can be created in factories and quickly assembled into 3D units on site. This can be highly time and labour efficient. Volumetric construction can also involve 3D or prefabricated units being created at a factory, before being transported as full structures ready to be put into place. Hybrid MMC approaches can be used to combine both panellised and volumetric techniques.

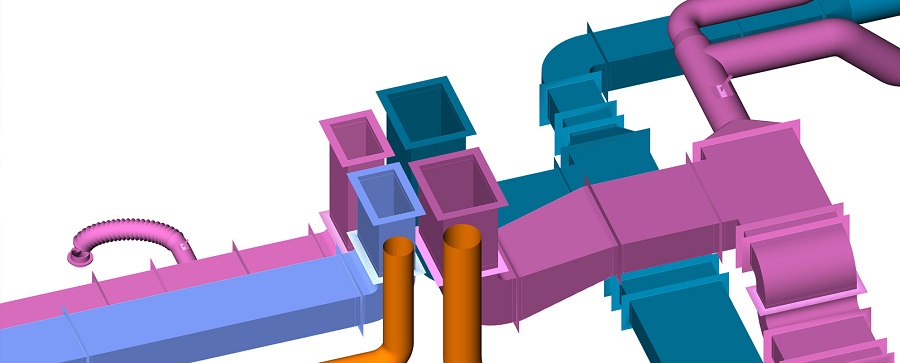

Building Information Modelling (BIM)

Building Information Modelling (known as BIM) uses AI and computer technology to plan and mock-up the full construction process, from start to finish. Architects through to structural engineers and builders can work together to visualise the build’s process before it begins. BIM is seen as part of an advanced type of MMC technology, along with 3D printing and the use of robots in construction. BIM helps to streamline processes and imagine problems before they happen, but it’s costly to use. (use image example)

Floor or roof cassettes

Floor and roof cassettes can be pre-cast off-site in factories and transported to the site for use. Examples include prefabricated floor panels, roof panels and dormers. This technique is popular for a diverse range of building types, and does still require specialist construction labour on site, but helps to improve the efficiency of the build.

Foundations and wiring

Innovative tunnel form or thin-joint block work techniques can be used to create pre-cast concrete foundations and even pre-formed wiring looms for buildings, which can greatly reduce construction time, mess, labour costs and the risk of material wastage.

Other MMC types are precast concrete walls and floors - including twin wall technology - and thin joint masonry.

When did modern methods of construction start?

Modern methods of construction began in the UK in the early 20th Century, notably in post-war Britain when housing was needed quickly and cheaply, but contemporary techniques are continuously being developed to meet modern demands. During the housing crisis in 2005 the popularity of MMC rose, and in 2017 The National House Building Council (NHBC) endorsed an online MMC hub to help support more developers in adopting MMC methods.

What is the difference between traditional and modern construction methods?

Traditional building methods usually involve bricks and mortar, with the process following a set linear construction pattern (eg. the foundations must be in before you start building the walls), whereas modern construction methods involve prefabricated aspects being built off-site in a factory, which can follow a non-linear pattern (eg. the roof can be built at the same time as the walls).

MMC techniques aim to save time and improve quality and efficiency. They can be used for building whole homes, offices or sports halls. It isn’t always a suitable option, such as a developer may want to employ a traditional method for creating a character property in a conservation area, but a new school building would be an ideal option for MMC, as it could be built quickly whilst offering a safer structure than RAAC. It’s also possible to employ hybrid methods using aspects of MMC.

Advantages and disadvantages of MMC

MMC offers a wide range of advantages, most notably being cost effective, fast and high quality. Currently, there is a strong focus on energy efficiency and sustainability, which is where prefabricated building technologies can offer innovative solutions as well as potential cost savings. However, they do come with certain drawbacks, which we’ll look at below.

Advantages of modern methods

Modern methods of construction offer a versatile way of building which takes advantage of modern technologies and techniques. Its innovative process means construction timelines can be reduced, as well as labour costs and reducing the risk of damage as the building goes up. Multiple aspects of the construction can take place at once, and enhanced quality control in factories can reduce the risk of error before items reach the site.

Here are some of the key MMC advantages:

-

Versatile and modern way to create a variety of buildings

-

Time saving and can streamline construction timescales (including removing the first fix requirements on site)

-

Multiple aspects can be worked on at once

-

Labour costs may be reduced

-

Safety and risk management can be improved by moving hazardous jobs to safer factories

-

Sustainability can be improved by using modern materials

-

Buildings can become more carbon-neutral once built

-

Eliminates unnecessary waste of materials

-

High quality which can be assessed in the factory before shipping

-

Smaller margin of error for prefabricated pieces made under strict conditions

-

Less chance of weather damage, theft or vandalism during construction

Disadvantages of modern methods

Although the advantages of modern methods of construction are clear, there are some disadvantages to the practice. MMC remains less widely used in the UK than in other EU countries, and some builders are wary of its early onset costs and potentially complex planning procedures and site preparation. Others have criticised MMC designs, the risk to traditional jobs and the risk of structural fragmentation.

Here are some of the disadvantages of MMC:

-

Some people don’t like how modular styles look

-

Traditional construction methods become obsolete, risking traditional jobs

-

Accurate planning is essential in early stages, otherwise more complex problems may need to be fixed later on

-

The initial cost outlay is high (including when using BIM)

-

Safety and security risks for untrained staff handling components on site

-

Specialist equipment is needed

-

Structural fragmentation remains a risk if not properly assembled

-

Some UK planning teams remains cautious of MMC and modular buildings, unlike countries such as Scandanvia who have adopted MMC more widely

Although MMC offers an innovative choice for certain building types, an appetite still remains for more traditional building techniques in this country. However, hybrid options are an ever-increasing and cost-efficient way of building homes, schools, sports halls and businesses.

Find out more about the latest Building Regulations, as well as other useful construction information, on our dedicated Trade News and Advice hub.

Construction methods: FAQs

What are the advantages of modern methods?

Modern methods of construction offer a versatile way of building which takes advantage of modern technologies and techniques. Its innovative process means construction timelines can be reduced, as well as labour costs and reducing the risk of damage as the building goes up. Multiple aspects of the construction can take place at once, and quality control in factories can reduce the risk of error before items reach the site.

What are the disadvantages of modern construction methods?

Although the advantages of modern methods of construction are clear, there are some disadvantages to the practice. MMC remains less widely used in the UK than in other EU countries, and some builders are wary of its early costs and potentially complex planning procedures and site preparation. Others have criticised MMC designs, the risk to traditional jobs and the risk of structural fragmentation.

What are modern construction materials?

Modern construction materials include prefabricated timber frames, 3D modular buildings, precast panels, hot rolled fabricated steel, light gauge steel frames, precast concrete foundations, pre-formed wiring looms, thin wall technology, BIM, thin joint masonry and precast floor or roof cassettes. MMC buildings can use prefabricated materials or a hybrid combination of traditional and modern.

Is BIM a modern method of construction?

Building Information Modelling (known as BIM) uses AI and computer technology to plan and mock-up the full construction process, from start to finish. Architects through to structural engineers and builders can work together to visualise the build’s process before it begins. BIM is seen as part of an advanced type of MMC technology, along with 3D printing and the use of robots in construction.

What is the difference between traditional and modern construction methods?

Traditional building methods usually involve bricks and mortar, with the process following a set linear construction pattern (eg. the foundations must be in before you start building the walls), whereas modern construction methods involve prefabricated aspects being built off-site in a factory, which can follow a non-linear pattern (eg. the roof can be built at the same time as the walls).

Disclaimer: The information contained on this page is intended as an overall introduction and is not intended as specific advice from a qualified professional.